A ball screw is a straight mechanical actuator that interprets rotational movement to direct movement with little erosion. A strung shaft gives a helical raceway to ball heading which goes about as an exactness screw. Just as having the option to apply or withstand high push loads, they can do as such with minimum inner grating.

Y Axis Ball Screw

Y Axich ball screw is made to close resilience and are therefore reasonable for use in circumstances in which high exactness is necessary. The ball assembly goes about as the nut while the strung shaft is the screw. As opposed to ordinary lead screws, ball screws will, in general, be rather bulky, because of the need to have an instrument to re-flow the balls.

Our custom Y Axis Ball Screw can be planned with a decision of return systems, with virtually any lead and either full sweep or Gothic curve string forms. All external return congregations include consistent return cylinders, and all inner flop over structures are mechanically racked and collected from within the ball nut as a safety highlight. All ball screws have and nylon, brush or felt wiper seals shield the direction from sullying.

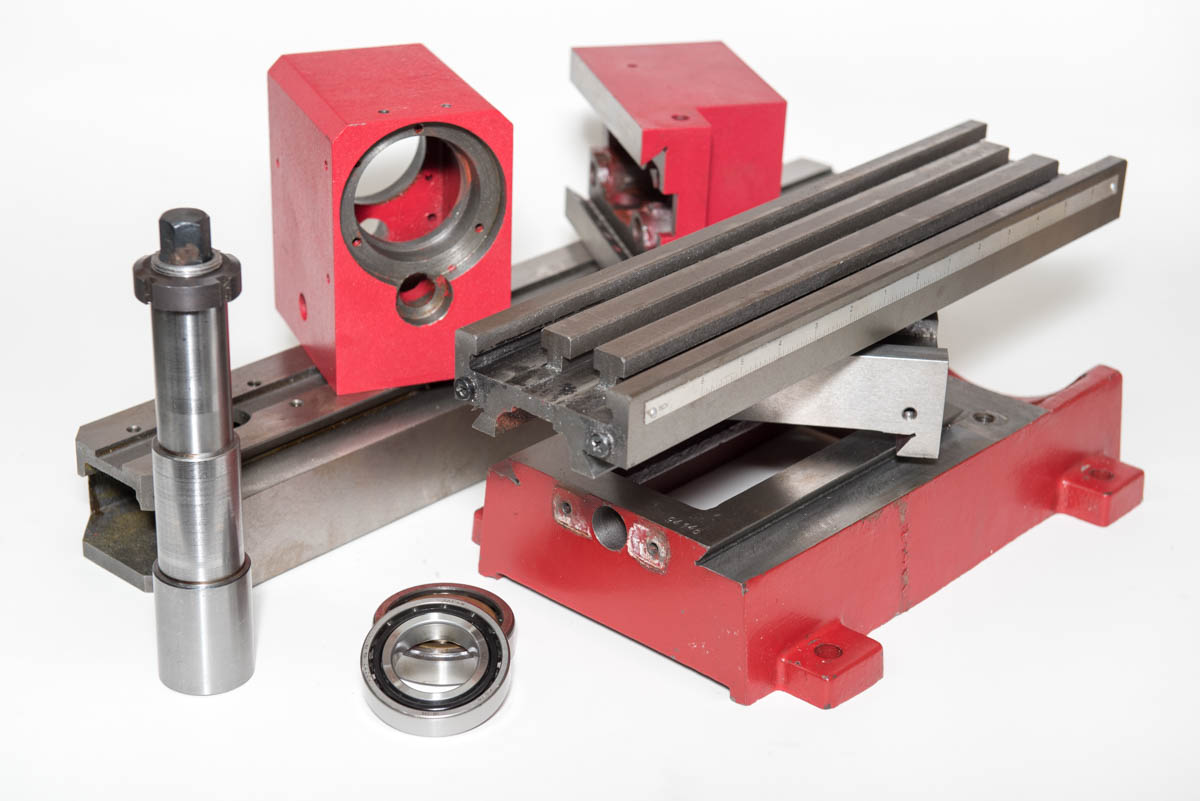

Machining the X and Y Mounts

X and Y mount soon after I machined them from 7/8″ aluminize stock. The parts, despite everything, should be tapped and debarred. Tabs were utilized to hold the pieces set up in the capital while machining. I cut the parts free later with a metal cutting band saw however you could use a hack saw.

Y Axis Ball Screw drive system

Comprised of a nut, screw, and ball orientation, ball screw drive systems work like typical force screws; however the moving contact replaces the sliding grating. As the screw turns, the machine moves.

What does Y Axis Ball Screw progress nicely?

At the point when done correctly, ball screws have exceptional accuracy and are without grinding, sliding smoothly with the movement. There are, likewise, additionally mounting choices. Racks must be darted to something for their whole length, where Y Axis Ball Screw may be a superior fit for some machine plans. Ball screws systems are likewise simpler to use in the assembling procedure, where rack and pinion may require more methods to be constructed correctly.

Would I be able to utilize the Y Axis Ball Screw accordion covers from my different mill?

No, they won’t work with the new mill seat and ball leadscrews. The X/Y saddle is a lot taller ready screw mill than on the standard leadscrew mill, and therefore, the metal plates of the accordion covers were expanded in size accordingly.

Does the Y Axis Ball Screwdespite everything take into consideration manual control?

The stepper motors Y Axis Ball Screw have handwheels on them so you can accomplish manual work. The only disadvantage is that the ball leadscrews only arrive in a measurement pitch. Therefore, the handwheels only have metric graduations. This isn’t to say you can’t run an inch arrangement. You can likewise run measurement programs utilizing an inch control screen and the other way around.